slip ring

A conductive slip ring, also known as an electrical slip ring or rotary electrical joint, is an electromechanical device used to transmit power, signals, or data between rotating and stationary components. Its core function is to allow continuous rotation of equipment while maintaining stable and reliable electrical connections, avoiding wire tangling issues caused by rotation. The conductive slip ring achieves power or signal transmission between rotating and stationary parts through sliding contact between brushes and rings. Conductive slip rings are indispensable key components in modern industry, and their performance directly impacts the operational efficiency and reliability of equipment. Choosing high-quality conductive slip rings can significantly enhance the overall performance and service life of equipment.

Single way rotary joint

A single-channel gas/liquid rotary joint is a device used to transfer gas or liquid between rotating and stationary components. It enables stable transmission of gas or liquid media while the equipment rotates continuously, avoiding issues such as pipe tangling or leakage. The single-channel design means that the joint supports the transmission of only one type of gas or liquid medium, making it suitable for applications with simple structures and single functions. Examples include pneumatic rotary joints, hydraulic rotary joints, high-temperature-resistant rotary joints, and corrosion-resistant rotary joints.

Multi way rotary joint

Multi-channel gas/liquid rotary joints, also known as multi-passage gas/liquid slip rings, are devices used to simultaneously transfer multiple gas or liquid media between rotating and stationary components. They enable stable transmission of various media (such as gas, hydraulic oil, water, etc.) while the equipment rotates continuously, avoiding issues such as pipe tangling or leakage.

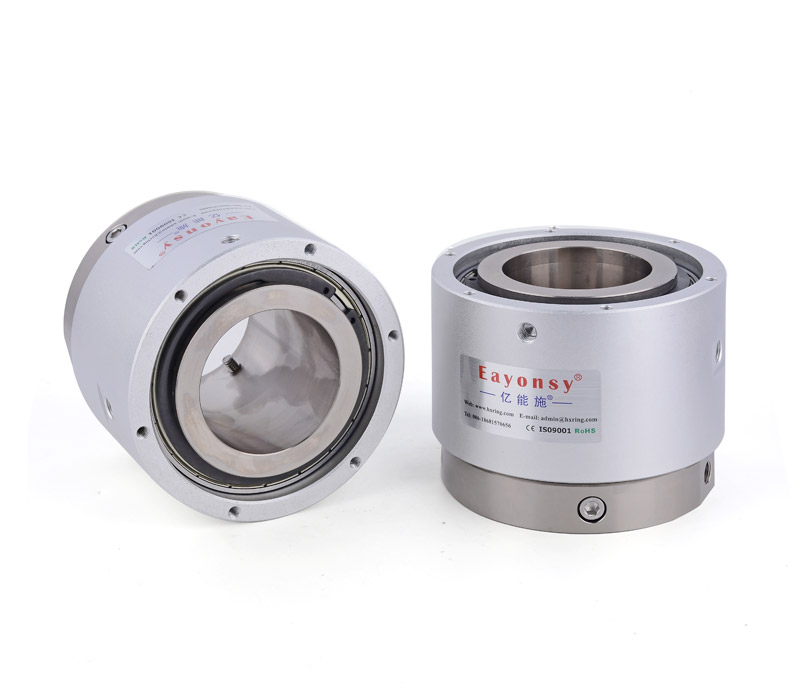

Large aperture slip ring

Large-bore rotary joints, also known as large-bore fluid and gas rotary unions, are precision devices used to transfer gases, liquids, or mixed media (dual-purpose for gas and liquid) between rotating and stationary components. Their core feature is a large central channel (bore), making them suitable for high-flow applications or scenarios requiring the passage of large-diameter pipelines. They enable stable transmission of media (such as hydraulic oil, compressed air, coolant, etc.) while the equipment continues to rotate, and also support multi-channel integration (e.g., electrical signals, optical fibers, etc.).

Gas electric combination slip ring

The combined fluid, gas, and electrical slip ring (also known as the integrated fluid, gas, and electrical slip ring) is a multi-functional rotary transmission device capable of simultaneously transferring gases, liquids, and electrical signals (or power) between rotating and stationary components. It integrates gas paths, liquid paths, and electrical circuits into a single unit, simplifying equipment structure. It is widely used in complex rotating systems that require the simultaneous transmission of multiple media.